Environment

The World's First 'Green Shipyard'

Environmental Vision

Since the announcement of the “Green Shipyard” in 1996, We have put the environment first in its management principles and

pursued green and sustainable growth while conserving natural resources.

We have gained a green competitive edge by minimizing pollution on the production line, running a wind power businesses, developing environmentally

friendly vessels, and CO2 capture technology.

We strive to realize the vision as a global environmental leader through implementing a pollution-free workplace, eco-friendly competitiveness,

and global green management.

Environment Policy

1 Comply with the environmental regulations and minimize pollution and waste

Consistent development of environmental technology to reduce raw material and energy consumption

2 Employees play a role as Green Agents

Provide consistent environmental training and practice eco-friendly activities

3 Environmental accident prevention/inspection activities

Autonomous prevention and inspection activities for potential environmental pollution

cause in the entire production processes for efficient environmental management

4 Continuous 3R Movement

Reduce, reuse, and recycle for continued environmental improvement

5 Transparency in dealing with environmental information

Regular public release of information to maintain the transparency in execution of environmental policy

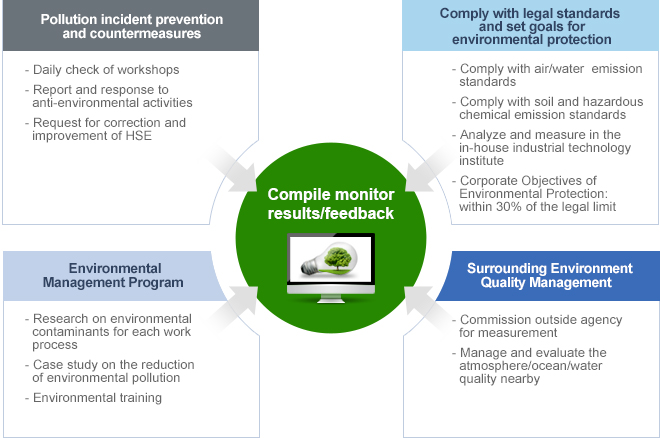

Environment Preservation Activities

We perform various activities to reduce pollution and waste and to preserve the environment around our workplaces.

Greenhouse Gas and Energy Reduction

We voluntarily implemented the greenhouse gas inventory to manage greenhouse gas and gets itself ready for

the future emission trading system through a MRV system.

Workplace Air Preservation

We run regular air control around the workplace and its vicinities in order to protect the health of employees and the people in the community. We also preserve the

air environment through an air pollution prevention system in ship building production by keeping the internal regulation level lower than 30% of legal limit.

Sewage/Waste Water Treatment and Recycle

The sewage/waste water from the different areas of the shipyard is collected in the local repository, transferred to the general sewage/waste water treatment facilities, a

nd managed at a level lower than 30% of the legal limit. Moreover, the water is treated with deuterium oxide and supplied to be reused in the shipyard.

Marine Environment Protection Campaign

We have its own marine protection vessels to remove marine floats in the shipyard area and to prevent marine environmental

pollution in cooperation with the government and the local community. The company's volunteer group is leading marine environment

and ecology protection through its 'One Company for One Clean River' campaign, coastal cleanup, and water purification campaign.

Recycle Campaign

Production Information System minimizes the amount of waste in the production process,

and the waste is sorted into nine categories, such as metal scraps and flammables and non-flammables, to be recycled based on 3R.

Toxic Chemical Control and Soil Pollution Prevention

Chemical treatment, usage and discharge are thoroughly controlled by Toxic Chemical Control Regulations.

The soil and the underground water are regularly monitored and examined by the inspection agency designated by the Ministry of Environment.