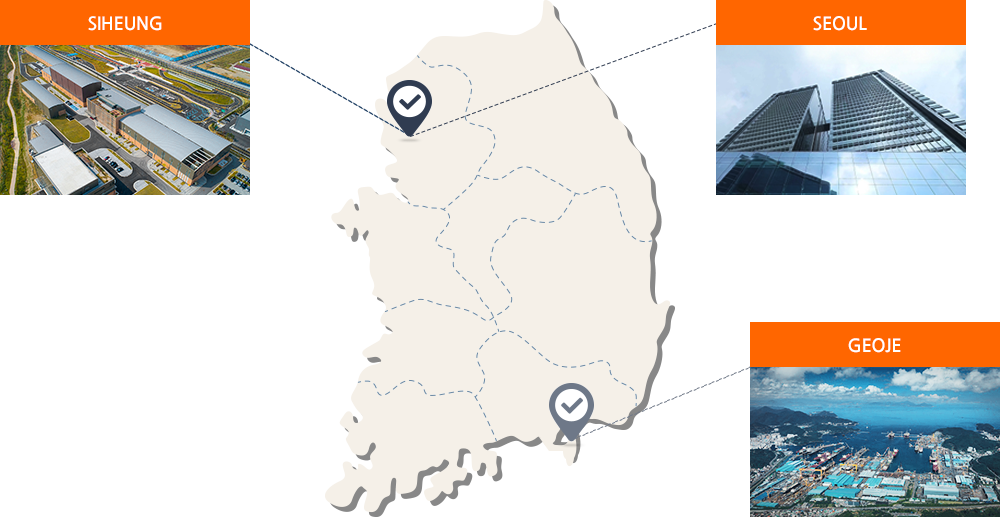

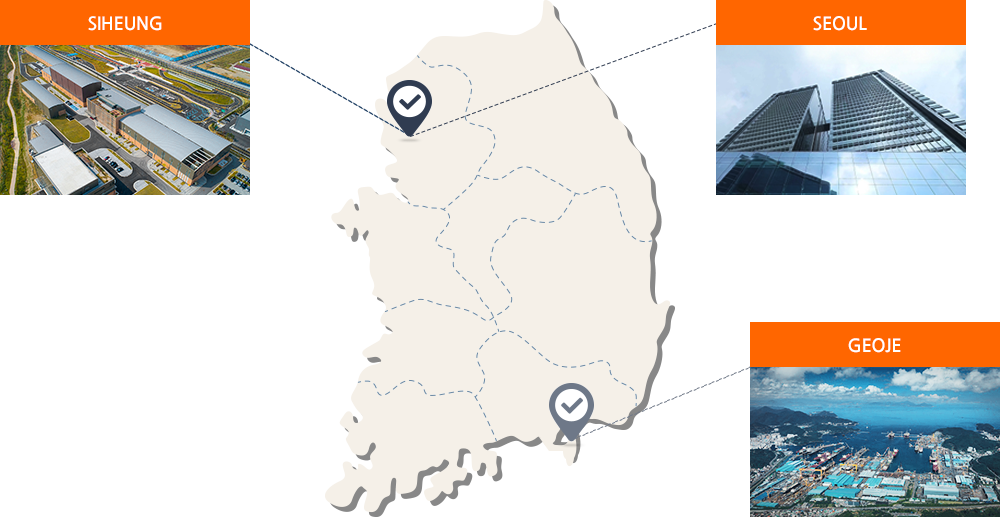

R&D

The World’s Leading Research and Development Center in Maritime Industry

Our R&D Centers are leading the technological development of commercial ships, offshore plants, and naval ships as the company's future growth engine.

To this end, we have state-of-the-art research facilities and excellent research professonals in Seoul, Siheung, and Geoje.

Performance Innovation Research Center

Focusing on naval architecture's core technologies, such as hull/propulsion, fluid dynamics, structures, and vibration/noise, we develop and commercialize innovative products to create new value.

- Developing innovative propulsors and Energy Saving Devices, including wind-assist propulsion systems

- Conducting global performance evaluations for ships and floating structures, including seakeeping, maneuvering, and structural assessments

- Developing vibration/noise reduction devices

Future Energy Research Center

We are leading the development of technologies in response to the energy transition, researching and developing decarbonization and eco-friendly energy technologies through technology and product differentiation based on zero-carbon fuel propulsion and transport.

- Developing core technologies for LNG carriers, including storage and processing systems

- Developing fuel transition response technologies, including low/no carbon fuel-based ship propulsion systems

- Developing future/decarbonization (hydrogen and CO2) ships and carbon emission reduction technologies

Manufacturing Innovation Research Center

We are responsible for materials and process development and production technologies, including automation systems, for producing various products such as shipbuilding, marine, and special vessels, aiming to improve productivity.

- Developing robotics and automated equipment/systems

- Developing welding techniques/materials and processes

- Developing coatings/polymer materials and processes

Technology Consulting Center

We support the application of new technologies related to welding, painting, vibration and noise, autonomous navigation, etc., and solve complex technical problems on-site through various model tests and numerical analysis for performance evaluation.

- Evaluating and solving on-site application problems for R&D prototypes

- Conducting model tests in towing tanks and cavitation tunnels and developing techniques

- Conducting model tests and performance evaluation for sloshing impact loads

Smart Solutions Research Center

We aim to lead the market of eco-friendly advanced ships and improve their safety and efficiency by integrating autonomous navigation, digital solutions, and automation/electrification technologies.

- Developing autonomous navigation and eco-friendly economic operation optimization solutions

- Developing foundational systems for autonomous ships and AI-based ship management and maintenance solutions

- Developing electric propulsion systems and equipment automation

Defense Technology Research Center

As the first defense-specialized research center in a domestic shipyard and a future growth engine for Hanwha Ocean's defense technology, we collaborate with the special vessel organization to lead technological advancement in the special vessel sector.

- Developing integrated survivability analysis/evaluation systems for warships and signal reduction technologies through special performance analysis

- Developing armament systems for warships, unmanned systems, and smart ship technologies

- Developing next-generation AIP technology for submarines and electric propulsion systems for surface ships

Facilities

-

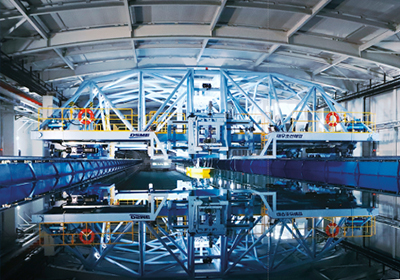

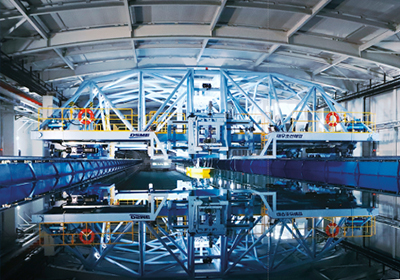

- Towing Tank (300m x 16m x 7m)

- Scaled-model test facility for ship propulsion, maneuvering, and seakeeping performance in realistic sea conditions.

-

- Cavitation Tunnel (13m x 2.8m x 2.4m)

- Propeller cavitation performance test facility for commercial ships & naval vessels.

-

- Acoustic Water Tank (25m x 15m x 10m)

- Acoustic characteristics measurement and analytical test facility using underwater sound waves.

-

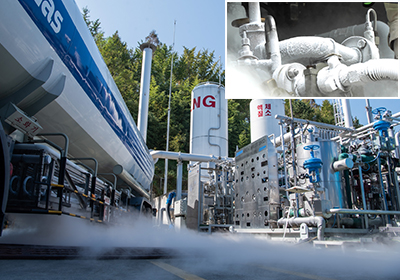

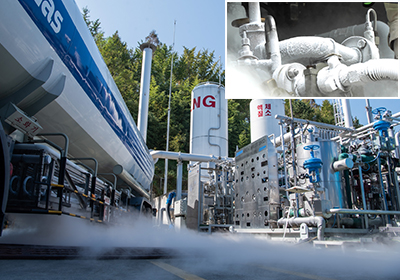

- Eco-friendly Fuel LBTS (Land Based Test Site)

-

Facility for R&D and demonstration of eco-friendly fuel systems.

-

- HS4(Hanwha Ocean Smartship Solution) Onshore Operation Center

-

Facility to provide web-based smart services utilizing marine data analytics with data collected via satellites in order to support client’s more efficient and safe operation.

-

- Smart Yard Operation Center

- Facility to optimize and improve production activities and support rapid decision making through connectivity, automation, and intelligent manufacturing.

-

- Intelligent Production Technology R&D Center

- Digital transformation research and eco-friendly and safe production devices development facility.

-

- Energy System Research Center

- Performance and endurance test facility for various LNG systems.

-

- Sloshing Research Center

- Model test facility to predict and respond to sloshing loads.