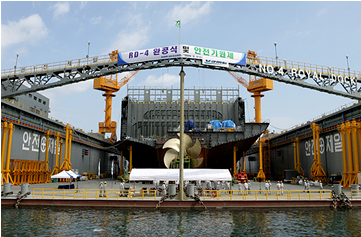

Hanwha Ocean

- Our Company

Challenge, Dedication,

IntegrityThese are the core values

that drive us to be the best at

what we do. - Business Areas

As a leading shipbuilder,

we pursue technological

excellence to lead the market

and achieve sustainable growth.With a focus on core technologies,

we pave the way to a brighter future. - R&D

Differentiated Technology,

Professionalization of ResearchWe maximize technological synergy

through efficient use of the research

and development system and diversify

driving forces for future growth. - Investor Relations

Realize the Investment Value

Through a Clear Vision and

StrategyWith a sound and transparent company

management structure centered on the

board of directors, We maximaize

the shareholder and company's values. - Press Room

Drawing upon our strengths

and experiences from the

past and present,We deliver lively news for happier

days and a better tomorrow. - Sustainability

A company that adds value to the world.

We plan for a better tomorrowWe strive to be a company to share hope

for the future with everyone in this society

and make this world a more beautiful place.